Metal Stock

Nickel Alloy

This durable metal brings exceptional corrosion, oxidation and temperature resistance combined with a high degree of ductility and formability.

Nickel Alloy

This durable metal brings exceptional corrosion, oxidation and temperature resistance combined with a high degree of ductility and formability.

Stainless Steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion.

Stainless Steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion.

Low Carbon Steel

Low-carbon steel low strength while making it more malleable and ductile compared to high-carbon steel.

Low Carbon Steel

Low-carbon steel low strength while making it more malleable and ductile compared to high-carbon steel.

View our stock below

Our inventory is carefully curated to meet a wide array of needs, ensuring that you have access to the latest and most sought-after products

View our stock below

Our inventory is carefully curated to meet a wide array of needs, ensuring that you have access to the latest and most sought-after products

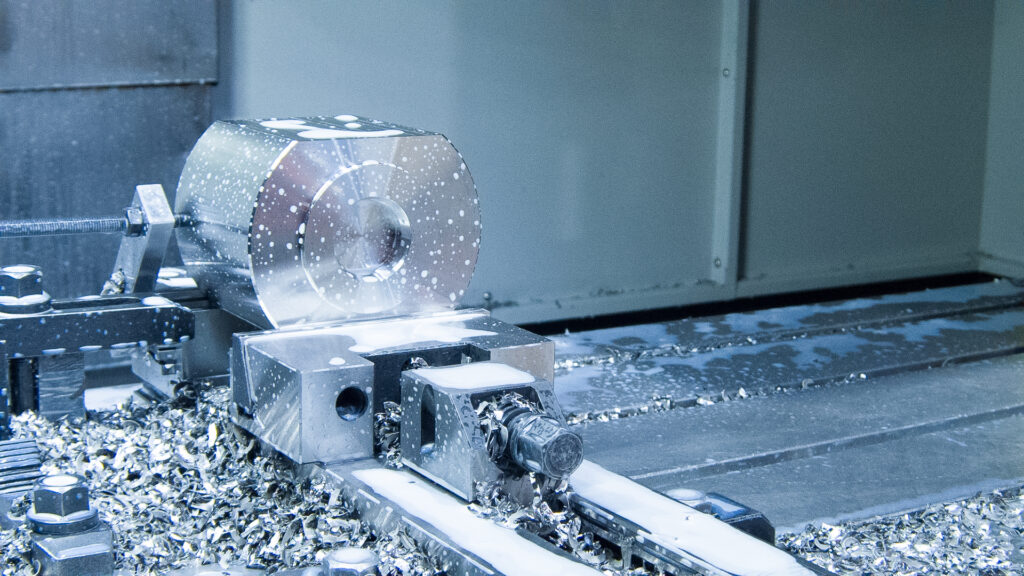

IEP can provide efficient

project management

International Energy Products holds a selection of ingots of varying sizes suitable for forging for large scale projects to specification.

All our products are held in various conditions with a selection of surface finishes and our size range runs from 1” to 20” in diameter. We can cut up to 620mm in diameter, and with a storage capacity of 100,000 square feet, our stocking solutions reduce the need for stockholding facilities.

We provide efficient project management of subcontract processing inclusive of heat treatment, forging, deep hole boring, machining, testing and inspection.

What nickel alloy products do you supply?

Nickel Alloy 718

Also known as Inconel 718, a high strength superalloy which is durable even in temperatures up to 650 degrees celsius.

Nickel Alloy 625

There is a stronger focus on a resistance to oxidation for nickel alloy 625 than 718, and is resistant to the effects of seawater.

Nickel Alloy 925

Very strong and resistant to pitting, crevice corrosion, and stress-corrosion cracking.

Nickel Alloy 725

Also known as Inconel 725, it is strong and resistant to corrosion. It also hardens over time.

Nickel Alloy 825

Alloy 825 is probably the most cost effective around sulphuric acid. It’s useful for pressure vessels, and can stand temperatures up to 525 degrees celsius, but not above as there is a risk of rupture.

Nickel Alloy 800

This nickel-iron-chromium composition doesn’t carburate or oxidise at high temperatures.

Nickel Alloy 660 a/b/c condition

Stainless steel with a high nickel content, used in temperatures up to 700 degrees celsius

Nickel Alloy 400

Nickel-copper alloy with a high resistance to a number of highly corrosive environments.

Nickel Alloy 20

Excellent corrosion resistance due to the combination of nickel-iron-chromium alloy with carbon, molybdenum and copper.

Nickel Alloy 28

Nickel-iron-chromium alloy again with the additions of molybdenum and copper to improve its resistance to acids and prevent corrosion cracking.

What stainless steel products do you supply?

Stainless Steel F51

Duplex stainless steels have a high chromium content, as well as moderate amounts of nickel and chromium. It has a good strength, and good resistance to corrosion and pitting.

Stainless Steel F55

This is composed of a higher chromium level with tungsten added. It is ideal for resisting corrosion in seawater and other chloride containing environments.

Stainless Steel F53

Duplex stainless steel F53 also offers a higher chromium content which protects better against pitting corrosion.

Stainless Steel 316

With high levels of chromium and nickel, it has a melting point of 1399 degrees celsius where there is a risk of rupture.

Stainless Steel 420

High carbon steel which can be hardened through heat treatment, and is one of the hardest stainless steels. They are resistant to mild acids and fresh water under hardened conditions.

Stainless Steel 17-4 PH

This steel can be treated to a high level of hardness, and good strength, with corrosion resistance and machinability.

Stainless Steel 410

Good corrosion resistance which can be improved by hardening, tempering, and polishing.

Stainless Steel Nitronic 50

An austenitic stainless steel with a high level of nitrogen to improve strength and resistance to corrosion.

Low Carbon Steel 4130

Easily weldable and machined when tempered, and is more weldable than low alloy steel 4140 but isn’t as strong.

Low Carbon Steel 4145

Contains 0.2% Molybdenum, and has improved hardenability.

Low Carbon Steel 4140

Being stronger than low alloy steel 4130, 4140 isn’t as easily welded.

Low Carbon Steel LF2

Moderately strong, but not very resistant to corrosion.

Low Carbon Steel F22

Improved weldability over 4130 whilst having a good level of strength as well as strong impact properties.

Low Carbon Steel 8630

This low alloy steel is used widely in oil patch applications for connectors, hangers, and block valves.

Low Carbon Steel 4330v

This low alloy steel has higher hardenability and impact toughness than 4140.

What low alloy steel products do you supply?

Our Stock

If you have further queries or you want to make an order please head to our contact page or request a quote.